Broaching Machines

Styles of Broaching Machines

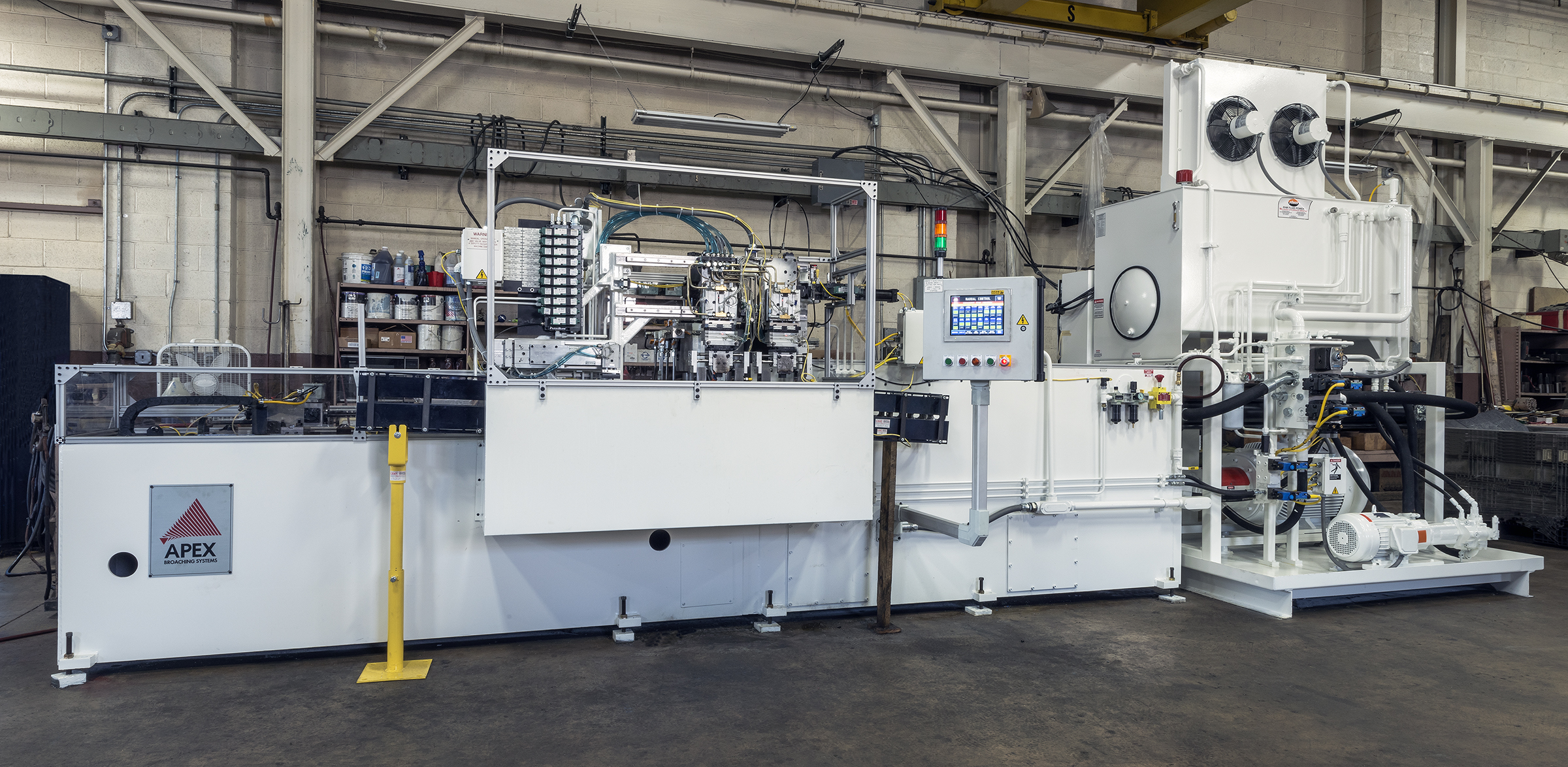

Our horizontal broaching machines are capable of handling a wide array of part applications such as internal splines, rifling, and keyways, with sizes ranging from 6 to 50 tons and strokes from 48" to 120". These machines provide several advantages, including floor-level operation, no need for a platform or pit, adaptable for CNC or Rack and Pinion movements....

Apex Broaching Systems offers a versatile range of Vertical Broaching Machines designed for high performance and precision in a wide array of part applications, including internal and external splines, rifling, and various forms and holes. Their Vertical Table-Up Broaching Machines feature floor-level operation with automatic tool handling and helical operation capabilities, ideal for high-rate cell manufacturing. Meanwhile, the Apex Surface Broaching Machines, available in both single and multi...

Blind Spline Broaching Machines are designed for precision in creating internal or external splines that terminate at a shoulder, rather than passing through the entire part. These machines utilize progressive broach tooling on a linear or rotating table for efficient, automatic loading and broaching of parts under a single vertical ram, enabling simultaneous machining of internal and external splines. Optimized for high production rates, Blind Spline Broaching surpasses traditional gear shaping...

The refurbishment process includes restoring all machining and qualifying surfaces to their original flat and square conditions, alongside refurbishing or replacing key components like the main motor, hydraulic power unit, and main slide. This process also involves machining or replacing ways, rebuilding or replacing the coolant and lube systems, updating the electrical system with new controls, and applying a fresh coat of industrial enamel paint. The refurbishment concludes with a comprehensiv...